Tool and Gage Makers are Essential in Manufacturing

Tool and Gage Makers are Essential in Manufacturing

Most people have a general idea of what a machinist is and the type of work they do. Tool and gage makers, on the other hand, aren’t as publicly recognizable, and many people have no clue what they do.

Like machinists, tool and gage makers are highly skilled tradespeople. They must be able to read and interpret complex engineering drawings, operate machining equipment such as mills, jig grinders, and lathes, and be proficient with computer-aided design (CAD) and computer-aided manufacturing (CAM) software.

Armed with these skills, tool and gage makers make precision fixtures, jigs, dies, molds, machine tools, gages, and more. Tool and gage makers typically work in tool rooms or a tooling department, rather than with production machinists on the shop floor.

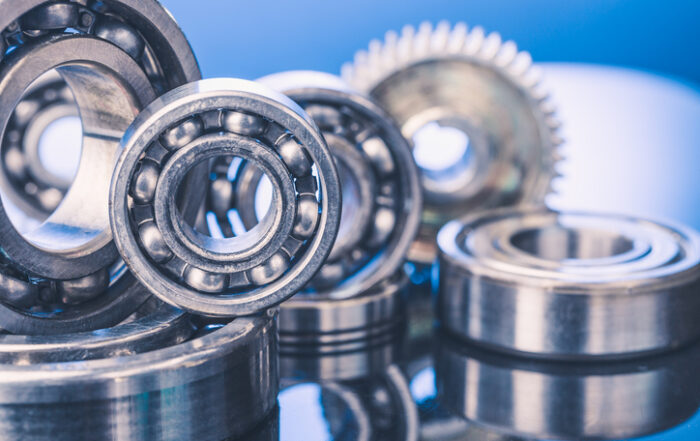

“Manufacturers who are making a product – whether that product is a ball bearing, or a part for a firearm, or an aerospace part – in order to machine that part on their machines they need a way to hold that part, they need a way to check that part, and that’s the tooling, the fixtures and the gages that we make for them”, Sirois Tool CEO Alan Ortner says.

Ortner says that many of his customers are manufacturers who employ machinists, but don’t have a tooling department. Other Sirois Tool customers have tooling departments, he notes, but they’re usually consumed with quick repair work that’s urgently needed to keep production moving. They rely on Sirois Tool’s experienced tool and gage makers for jobs with more lead time, or when they’re making a part for the first time and haven’t developed tooling for it yet.

Although Sirois Tool doesn’t have a design department, Ortner says they help their customers with tooling design. “We help our customers quite a bit in making tooling efficient to manufacture,” Ortner says. “They’ll quite often call us and ask, ‘what material should I make this out of? Are these tolerances too tight?’ So we help them as much as we can.”

About 47,500 job openings for machinists and tool and gage makers are projected each year in America, according to the U.S. Bureau of Labor Statistics (BLS), but skilled tool and gage makers are becoming increasingly scarce.

“Good toolmakers are an essential component of the manufacturing industry, but they’re hard to find,” Ortner says. To help fill the void, Sirois Tool partners with technical schools and apprenticeship programs. “For several years, we’ve worked with students from the manufacturing technology departments at local high schools and colleges. We give students behind-the-scenes shop tours and explain their career options at Sirois Tool. We also offer select students the opportunity to work with us while participating in the Department of Labor’s Pre-Apprenticeship program.”

The U.S. BLS reports that the median annual wage was $47,710 for machinists in May 2021, but the median annual wage for tool and gage makers was $57,000, 19.4% more. Sirois Tool typically pays above average compensation in addition to an excellent benefits package.

Whether the wage difference reflects a higher level of skill required for toolmakers, or the result of the current high demand and limited supply isn’t clear. One thing is certain: every tool and gage maker is a machinist, but not every machinist is a tool and gage maker.

Interested in a career as a tool and gage maker? Contact Us to learn more about Sirois Tool and the benefits we offer.

Share This Story, Choose Your Platform!

Recent News

Get Your Bearings (Before Manufacturing Them)

When someone is feeling unprepared, unsteady, or unsure, you might hear them say they need to “get their bearings.” It’s Read More

Sirois Tool Becomes Authorized Reseller of Mitutoyo Indicators for Dow Gages

Sirois Tool published a news release on April 5, 2025 announcing that it is now an authorized reseller of Mitutoyo Read More

Sirois Tool Featured in “Manufacturing in Focus” Magazine

In celebration of our 65th anniversary this year, we’re looking back at everything that’s happened with Sirois Tool over the Read More

Need A New Manufacturing Partner? Look For These Five Traits.

Mordor Intelligence estimates that the current $272.6 Billion market for satellite parts and components will surge to $417.7 Billion by Read More