Get Your Bearings (Before Manufacturing Them)

When someone is feeling unprepared, unsteady, or unsure, you might hear them say they need to “get their bearings.” It’s synonymous with saying they need more time to ensure they’re fully prepared and able to proceed with the task at hand.

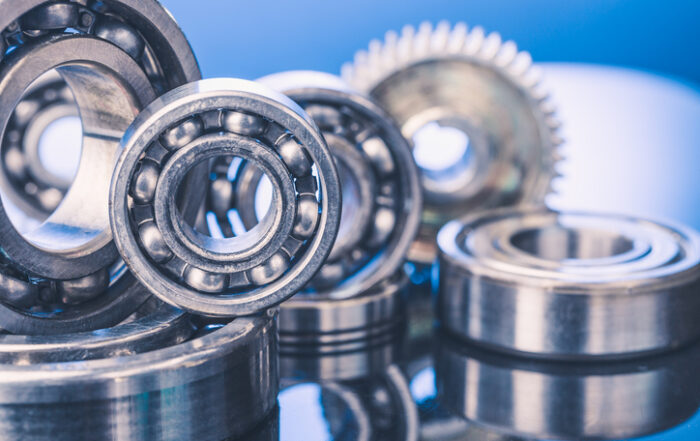

When it comes to manufacturing high quality bearings, you can’t be too prepared. Attention to detail and strict quality control throughout all processes is the key to producing reliable, high precision bearings.

We’ve provided tooling, fixtures, and gages for bearing manufacturers since 1960, and we’ve learned a lot about what it takes to manufacture them since then.

Material Considerations

Choosing the right bearing material is a critical first step, since choosing the wrong material can lead to premature bearing wear and/or failure. One lesser-known consideration is a material’s embeddability, which is its ability to absorb the foreign particles (i.e., dust grit, etc.) present in the lubricant. This is important because insufficient embeddability can lead to scoring and wear.

Strength, hardness, wear resistance, and fatigue strength are other key considerations.

Bearing manufacturers typically use high quality alloy steels such as Stainless Steel, Chrome Steel (52100), or ceramic materials because they offer excellent wear resistance, hardness, and fatigue strength.

Machining Methods

Strict adherence to proper tooling selection, precise part alignment, and optimum speed and feed control are necessary to achieve the tight tolerances and ultra smooth surface finishes bearings require.

Quality assurance also plays a critical role, since bearing tolerances are very tight. This is where Sirois Tool comes in.

Our custom tooling, fixtures, and gages, including our Dow Gages, are manufactured to assure bearings meet our customer specifications, even when the tolerances are as tight as +/- .0001.

Bearing manufacturers throughout North America rely on us because they know there are very few companies that can produce precision tooling, fixtures and gages as well as we can. After 65 years, our processes are finely honed (pun intended).

If your company wants to manufacture bearings more efficiently, reach out to us. We can manufacture tooling, fixtures, and gages that will help accelerate production and perform inspections in a fraction of the time it takes now.

In other words, we’ll help you “get your bearings.”

Share This Story, Choose Your Platform!

Recent News

Smart Technologies Help Smaller Firearms Manufacturers Compete

In March, Defense and Munitions magazine published an article titled “Industry 4.0 breaks barriers in custom gun manufacturing” that explained Read More

Three Reasons to Celebrate

We’re not even through the first half of the year yet, but 2025 has already given us three big reasons Read More

Get Your Bearings (Before Manufacturing Them)

When someone is feeling unprepared, unsteady, or unsure, you might hear them say they need to “get their bearings.” It’s Read More

Sirois Tool Becomes Authorized Reseller of Mitutoyo Indicators for Dow Gages

Sirois Tool published a news release on April 5, 2025 announcing that it is now an authorized reseller of Mitutoyo Read More