Focusing on the Entire Customer Experience Pays Off

Focusing on the Entire Customer Experience Pays Off

There’s an old adage when it comes to manufacturing: customers want quality, speed, and low cost, but they can only have two of these three things. At Sirois Tool, we disagree. We believe customers can have high quality products, delivered on time, and for a reasonable price. We know that manufacturers who consistently deliver these three things are less likely to lose their customers to competitors.

But product quality, timely delivery, and low cost aren’t enough. The manufacturing industry is highly competitive, and it takes much more than this to build lasting customer loyalty.

Exceptional customer service must be part of the package. How a company interacts with customers before, during – and especially after – the sale will strongly influence customers’ attitudes about the company. A delighted customer might provide a good recommendation, while one angry customer venting online could cause irreparable harm. Guess which customer is more likely to share their experience?

According to a Forbes magazine article titled “50 Stats That Prove the Value of Customer Experience”, customers tell an average of nine people about a positive experience with a brand, but they tell 16 people about a negative experience. And a whopping 96% of customers say customer service is important in their choice of loyalty to a brand.

Assuming your company already has exceptional customer service and consistently delivers on quality, speed, and cost, what else can you do to keep your customer base from shrinking?

Regularly communicating with your contacts (even those who haven’t made a recent purchase) can help. Checking in with them lets them know you’re taking care of them. If a contact changes companies, reach out to them via LinkedIn a few weeks into their new position. This will demonstrate your commitment to a lasting partnership. Similarly, if there’s a new contact working for an existing customer, send them a note welcoming them. Offer to meet with them to share what you currently do for their company, and what else you might do for them.

Recently, one of the customers we serve was purchased by a European company. While many might see this as a problem, we saw it as an opportunity. Working with our local contacts as well as the new company’s overseas representatives we’ve been able to continue many long term agreements for parts and subassemblies. This success was in spite of the transfer of ownership and other significant changes.

This recent acquisition is an example of how dynamic our industry is. Mergers, personnel changes, new technology, supplier shortages, the overall economy, and other conditions beyond our control can change suddenly and negatively impact our businesses. To minimize the potential impact, we all must take control wherever we can, especially when it comes to speed, quality, and cost. Reshoring can help.

Using domestic suppliers makes it easier to control quality and speed. It’s much easier to audit domestic suppliers and verify their certifications. Products shipped from domestic suppliers don’t take as long to arrive, either. Using offshore suppliers may seem more cost-effective up front, but any money you’ve saved on the product’s price won’t matter if your customers don’t get precisely what they ordered, exactly when they need it.

There’s another old adage in manufacturing that originated from Ben Franklin: “The bitterness of poor quality remains long after the sweetness of low price is forgotten.” This is one adage we can agree with.

At Sirois Tool, we’ve prioritized quality, speed, cost, and customer service for over 60 years. We communicate with our contacts regularly, too. Not just because it’s good for business, but because we are genuinely interested in how they’re doing, and how we might help them achieve greater success.

Contact Us to see how we can help you, too.

Share This Story, Choose Your Platform!

Recent News

Smart Technologies Help Smaller Firearms Manufacturers Compete

In March, Defense and Munitions magazine published an article titled “Industry 4.0 breaks barriers in custom gun manufacturing” that explained Read More

Three Reasons to Celebrate

We’re not even through the first half of the year yet, but 2025 has already given us three big reasons Read More

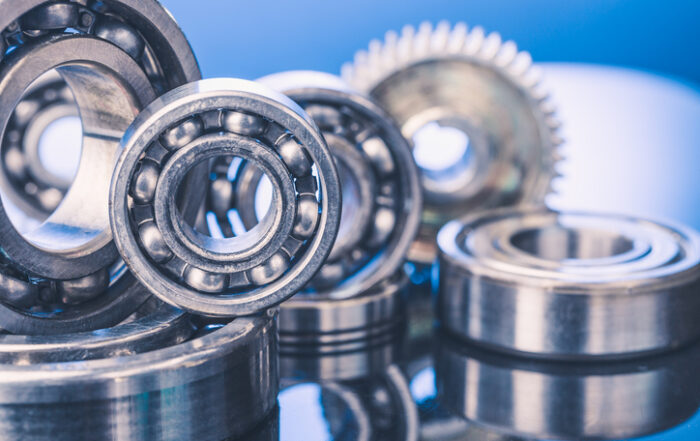

Get Your Bearings (Before Manufacturing Them)

When someone is feeling unprepared, unsteady, or unsure, you might hear them say they need to “get their bearings.” It’s Read More

Sirois Tool Becomes Authorized Reseller of Mitutoyo Indicators for Dow Gages

Sirois Tool published a news release on April 5, 2025 announcing that it is now an authorized reseller of Mitutoyo Read More